The words machinery and equipment can be used interchangeably, which may be confusing when transacting with used machinery dealers. Understanding the differences between machinery and equipment is particularly helpful for manufacturing and construction professionals. Here are some of the differences between equipment and machinery:

Differentiating Between Equipment and Machinery

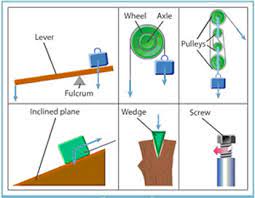

Machinery is a collection of mechanical devices with moving parts. These devices can be customized to perform specific tasks in industrial settings. Equipment refers to tools or instruments designed to perform a particular function. Unlike machinery, not all equipment has mechanical components. People may use the word equipment to refer to hand tools, protective gear, office furniture, and even computers. Used machinery dealers may categorize all machinery as equipment but cannot label all equipment as machinery. Here are some distinguishing features of machinery and equipment:

Mechanism

Machines typically have complex mechanical elements like motors and engines, which use energy. Machinery often includes multiple components, with moving parts like gears contributing to its functionality. Modern machines may have computer control centers and sensors. Because of its many components, machinery usually requires regular maintenance to maintain its functionality. Due to its complexity, you may also need a trained operator to work with machinery. Equipment typically has one or fewer parts compared to machinery. Most equipment has simpler or no mechanical elements, making it easier to operate and maintain.

Purpose and Functionality

Machinery is designed for specific functions in different industries. Cotton pickers are considered farm machinery because they perform the specific, complex function of harvesting cotton. People also use machinery to automate or streamline various processes. Some machines are operable using controllers, eliminating the need for human labor. Equipment serves a broader set of purposes and can include a variety of everyday tools and instruments. A tractor is considered equipment because it can serve various purposes in different industries. Most equipment is used for manual tasks and often requires some degree of human control or supervision. Many industries use equipment to support the functionality of their machinery.

Cost

Machinery is a significant business investment and usually costs more than equipment due to its mechanical complexity and functional specificity. The maintenance and operational costs for machinery may also be higher than for equipment. The cost of equipment depends on the individual piece’s size and complexity, so simple tools like power drills are less expensive than more complex equipment like tractors. Purchasing machinery from a used machinery dealer can offset the costs of new machinery and equipment.

Scale

Machinery is more heavy-duty than equipment, with larger and heavier pieces. Because of the size of heavy-duty machinery, you may need specialized equipment to transport it to and from your facility. Improper usage, installation, and transport of machinery may increase the risk of injury due to its large size. Because of these factors, machinery may have stricter safety requirements than equipment.

Industry Application

Machinery is commonly found in industrial settings like manufacturing and construction, where precision and power are required. Machines are also used extensively in large-scale agriculture. You can find equipment in nearly any business setting, including medical facilities, office buildings, and other environments where versatility and functionality are necessary. Machinery usually serves large-scale industry processes, while equipment serves smaller-scale industry functions.

Power Source

Machinery may use electricity, natural gas, or diesel as an energy source. They consume more power than equipment during operation. Most industries that depend on machinery have a backup energy source to minimize machinery downtime during power outages. Some machines are designed to operate using various power sources to facilitate continuous productivity. Equipment may be battery-powered, electrical, or manual and may have less versatility in their power sources.

Regulatory Compliance

Machinery is subject to strict regulatory and safety standards due to its complexity and potential risks for users. Industries that use heavy machinery must educate their staff on the dangers of working with the machines and the proper safety measures. Protective gear is commonly required when working with machinery. Equipment may have fewer and less strict safety requirements depending on its use. Some equipment may require users to wear protective gear.

Buy Machinery From Used Machinery Dealers

Consult a used machinery seller if you are unsure whether you need industry equipment or machinery. Used machinery dealers can advise companies in various industries and help them find machinery or equipment to serve their specific needs. A used machinery seller can provide cost-effective machinery for your business. Contact a dealer today to learn more about which pieces of used equipment and machinery can enhance your business’s operations.