Welcome to the world of conveyor belts – the unsung heroes of efficiency in businesses across industries. From moving goods seamlessly through production lines to streamlining operations, these silent workhorses play a pivotal role in maximizing productivity and minimizing costs. In this blog post, we’ll delve into how choosing the right conveyor belt can make a substantial impact on your business’s overall efficiency and success. Let’s explore the different types of conveyor belts, essential factors to consider when selecting one, real-life case studies, maintenance tips, and even innovative alternatives that could revolutionize your workflow. Stay tuned for valuable insights on optimizing your operations with the perfect conveyor belt solution!

- Different types of conveyor belts and their uses

- Factors to consider when choosing a conveyor belt for your business

- Impact of using the right conveyor belt on production and cost

- Case studies of businesses that have improved efficiency with the right conveyor belt

- Maintenance and care tips for maximizing the lifespan of your conveyor belt

- Alternatives to traditional conveyor belts and their benefits

- Conclusion

Different types of conveyor belts and their uses

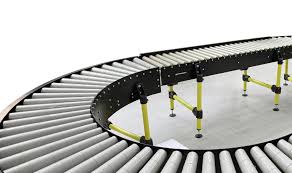

When it comes to conveyor belts, there are various types of conveyor belts designed for specific purposes.

- One common type is the flat belt conveyor, ideal for moving items smoothly on a flat surface.

- For inclined or vertical transportation, you might opt for a bucket conveyor that utilizes buckets to carry materials.

- If you need to transport heavy loads over long distances, a roller conveyor with rotating rollers can be your go-to choice.

- In industries handling loose materials like grains or powders, a screw conveyor works efficiently by rotating helical screws.

- For curved paths and flexibility in layouts, a modular belt conveyor offers versatility and adaptability.

- Wire mesh conveyors are great for high-temperature applications as they allow airflow and drainage while transporting goods seamlessly.

Understanding the different types of conveyors helps businesses choose the right one tailored to their specific operational needs.

Other types of conveyor belts include:

1. Magnetic belt conveyors: These use a magnetic bed beneath the conveying surface to transport magnetic materials.

2. Chain conveyors: These use a chain driven by sprockets to move materials along the conveying surface.

3. Slat conveyors: Similar to chain conveyors, slat conveyors use slats or plates to transport materials.

4. Pneumatic/Vacuum conveyors: These use air pressure or suction to move lightweight materials through tubes or pipes.

Factors to consider when choosing a conveyor belt for your business

When it comes to choosing the right conveyor belt for your business, there are several key factors to consider.

- The first thing to think about is the type of material being transported – whether it’s heavy-duty items or delicate products.

- Another important factor is the speed and capacity requirements of your production line. You’ll need a conveyor belt that can handle the volume without causing bottlenecks in your workflow.

- The environment in which the conveyor belt will operate is crucial as well. From temperature fluctuations to exposure to chemicals or moisture, these conditions can impact the durability and performance of the belt.

- Consider maintenance needs and ease of cleaning when selecting a conveyor belt. A low-maintenance option could save you time and money in the long run.

- Lastly, don’t forget about safety features. Ensuring that your employees are protected while working around the conveyor system should be a top priority when making your decision on which belt to choose for your business.

Impact of using the right conveyor belt on production and cost

Choosing the right conveyor belt for your business can have a significant impact on both production efficiency and cost-effectiveness. By selecting a conveyor belt that is specifically designed to handle the unique needs of your operation, you can ensure smooth and uninterrupted material flow throughout the entire manufacturing process.

An efficient conveyor system reduces downtime caused by jams or malfunctions, allowing for continuous production without costly interruptions. This results in higher output levels and improved overall productivity. Additionally, utilizing a conveyor belt that is tailored to your business requirements can help minimize waste and optimize resource utilization, ultimately leading to lower operational costs over time.

Moreover, investing in a high-quality conveyor belt means fewer maintenance issues and longer lifespan, reducing replacement frequency and saving money in the long run. Overall, the right choice of conveyor belt not only enhances production efficiency but also plays a crucial role in maximizing cost savings for your business.

Case studies of businesses that have improved efficiency with the right conveyor belt

Picture this: a bustling warehouse where products flow seamlessly from one end to the other, thanks to the perfect conveyor belt choice.

- Company A;

Company A saw their production rates soar after switching to a high-speed modular belt system. The ease of customization allowed them to adapt quickly to changing needs without major disruptions.

- Company B;

Over in another industry, Company B optimized their workflow by investing in a heavy-duty roller conveyor. Suddenly, moving heavy loads became effortless and workers were spared from physically taxing tasks. This simple change not only boosted morale but also reduced workplace injuries significantly.

- Company C;

And let’s not forget about Company C, who revolutionized their packaging process with an inclined belt conveyor. By eliminating manual labor and streamlining operations, they cut down on errors and saved precious time that could now be allocated elsewhere for further growth opportunities.

These success stories serve as proof that selecting the right conveyor belt can truly transform how businesses operate and thrive in today’s competitive landscape.

Maintenance and care tips for maximizing the lifespan of your conveyor belt

Maintaining your conveyor belt is crucial for ensuring smooth operations and maximizing its lifespan. Regularly inspect the belt for any signs of wear or damage, such as tears or fraying edges. Clean the belt to prevent debris buildup that could lead to malfunctions or premature wearing out.

Keep an eye on the tension of the belt to ensure it is properly aligned and not too loose or tight, which can cause unnecessary strain on the system. Lubricate moving parts regularly to reduce friction and prolong the life of the conveyor belt components. Train your staff on proper usage and handling of the conveyor belt to minimize user-induced damages. Schedule routine maintenance checks by qualified technicians to address any potential issues before they escalate into larger problems.

Investing time in caring for your conveyor belt will pay off in increased efficiency and cost savings down the line.

Alternatives to traditional conveyor belts and their benefits

Looking to explore innovative alternatives to traditional conveyor belts for your business?

- One exciting option gaining popularity is the use of magnetic conveyors. These systems utilize powerful magnets to move materials efficiently along a track, reducing the need for complex mechanisms and maintenance.

- Another emerging alternative is vacuum conveyors, which operate by creating suction to transport items through a tube system. This method can be particularly useful for handling delicate or powdery substances with precision and care.

- For businesses seeking flexibility in their material handling processes, modular belt conveyors offer customizable solutions that can easily adapt to changing production needs. By allowing for quick adjustments and configurations, these conveyors optimize efficiency while minimizing downtime.

Consider exploring these modern alternatives to enhance your operational efficiency and stay ahead in today’s competitive market!

Conclusion

In conclusion, making the right choice when it comes to conveyor belts is more than just a purchase – it’s an investment in the future success of your business. So take the time to evaluate your options thoroughly and choose wisely to unlock the full potential of your operations.

Choosing the right conveyor belt for your business is a crucial decision that can significantly impact efficiency, productivity, and costs. By understanding the different types of conveyor belts available and carefully considering factors such as material composition, belt size, and operational requirements, you can optimize your operations for maximum effectiveness.